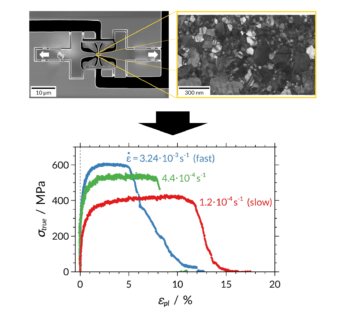

Nanomechanics and TEM for enhancing the ductility of metallic thin films

A cooperation between GRK and CENEM researchers unraveled the unexpected positive influence of grain boundary mediated plasticity on the ductility of metallic thin films, with far ranging consequences for applications.

The limited ductility of metallic thin films (< 1%) poses a challenge to MEMS and flexible electronics applications. A groups of GRK and CENEM scientists identified freestanding gold specimens with the remarkable ability to accommodate ≥10% plastic deformation while retaining a high strength. Using in situ nanomechanical testing in a transmission electron microscope, they traced this exceptionally high ductility back to the combination of an ultrathin thickness, a columnar microstructure and a (111) fiber texture. Under such conditions, the deformation is largely mediated by grain boundaries through grain boundary sliding and shear coupled grain boundary migration. Because these non-conventional mechanisms preserve the cross-sectional thickness of the specimens, necking is postponed and the samples can reach a high ductility. Since the mechanisms were evidenced at room temperature and under strain-rate conditions typical of most applications, the findings open up promising outlooks for developing ductile metallic films by microstructural engineering.

The research was published in the August 15 issue of Acta Materialia:

Liebig, J. P., Mackovic, M., Spiecker, E., Göken, M., & Merle, B. (2021). Grain boundary mediated plasticity: a blessing for the ductility of metallic thin films? Acta Materialia, 117079. (open access)